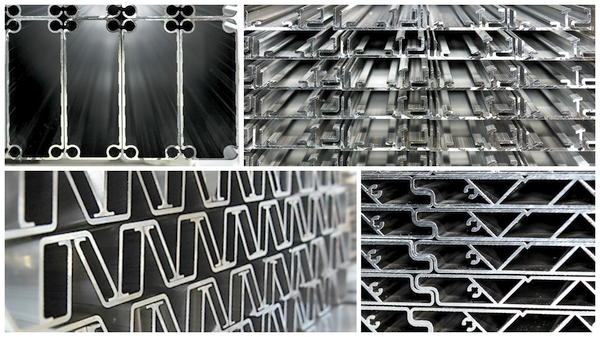

Extruded Aluminium Profiles Automatic Packing Line

Introducing a greener production process in aluminium production

A Greener Production Process

The Romanian-based aluminium company, Vimetco Extrusion, intends to implement greener production processes, and one of these processes is packaging of finished products. Converting to a green process involves moving from a manual to an automatic packing line. The Automatic line represents a completely new and innovative process for the company.

Depending on the manufacturing industry it is estimated that between 20% and 50% of total operating expenses are attributed to material handling – both materials and product. Optimizing the process layout can reduce costs by 10% to 50%.

By moving from a manual to an automatic production line, Vimetco aims to reduce costs, increase productivity, and reduce CO2 emissions.

Expected outcomes of the project:

- Increased labour productivity and cost optimization which will reflect on annual growth in turnover and net operational profit.

- Reduction of aluminium waste.

- Reduction of CO2 – because of the reduction of recycled aluminium.

- Reduction of fuel consumption because of the significant reduction of forklifts use.

- Reduction of packaging materials waste.

As a partner, IDN will assist Vimetco Extrusion in designing and implementing the automatic packaging and logistics solution. Using value stream mapping, Vimetco will be able to evaluate and integrate in the value stream to achieve a competitive advantage.