Improving productivity in Starco Beni Monastir factory by Karakuri Kaizen methodology

The project "Reinventing the wheel" aims at transitioning Starco Beli Manastir into a leading regional company with sustainability and energy efficiency in focus.

Development towards a long-term sustainable business model.

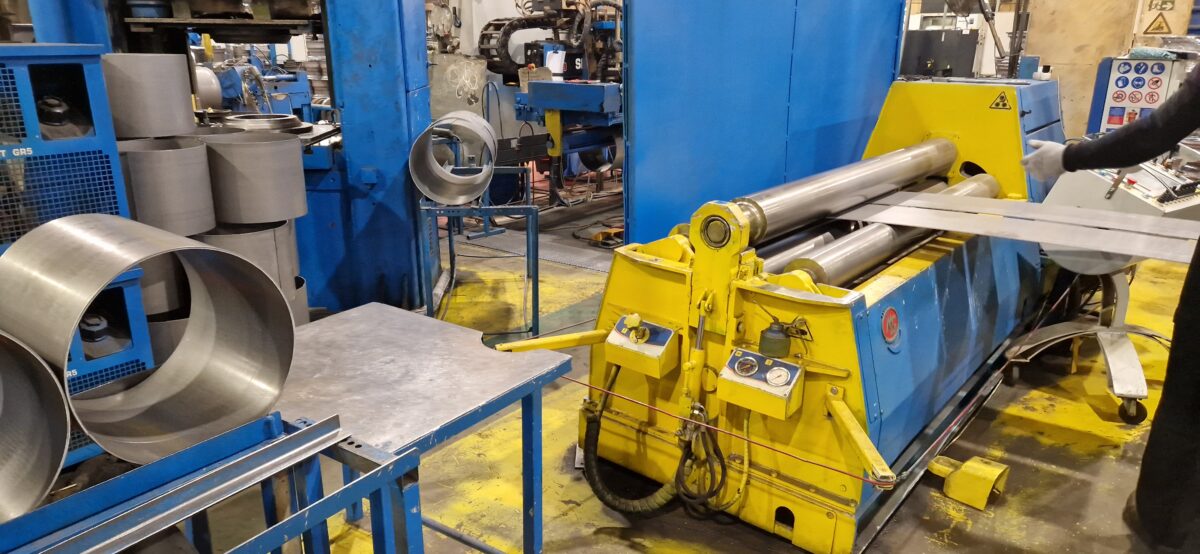

Starco Beli Manastir Ltd. produces niche car parts, particularly within the wheels and tire section of various automated machinery. Due to the rising market cost of raw materials over the last few years, the company cannot meet demand. The company is located in an underdeveloped region of Croatia stemming from the war. Scaling the enterprise according to demand and opportunities has its difficulties. Particularly when recruiting high-intensity labour and branching out to other actors. The project, therefore, focuses on how the company can be taken from a struggling regional company to a well-connected actor focused on using steel for rare and unique car parts. For this to be achievable, improved facilities, competitive and green products, and new infrastructure are essential for a directional change into innovative, socially responsible and green conduct.

The main objective will, therefore, be to reduce operational costs and completely remodel into a more sustainable and socially acceptable enterprise. While also increasing their competitive abilities and profitability in the long term. By 2033, it is expected that the CO2 produced per unit will decrease by 177,11 tons following the switch towards sustainability, while new high-skilled jobs will increase by 10 in the year 2038. This is a result of increased capacity, new facilities and better technology. Showcasing the potential investment in Starco Beli Manastir can achieve not only for the company but also for the Croatian region.

Measures:

- Creation of value chains, clusters and platforms for cooperation.

- Automated machinery to increase production capacity.

- Establish a Green and Lean factory.

- Implement monitoring systems to detect malfunctions on equipment quickly.

- Chemical removal plant building.

Role of IDN:

- Mapping, designing, and implementing the innovative Karakuri Kaizen solution for zero-energy production line transportation for products and materials related to establishing the living lab. It has multiple functions, such as a place for training and education both for Starco partners and externals.