Opportunities on the adoption of Industry 4.0: SME manufacturing sector

This is the second of four short articles with overview of drivers for digitalization, opportunities for SME manufacturers in Industry 4.0 and obstacles for Industry 4.0 adoption in SME industry sector.

Opportunities

Industry 4.0 provides enormous opportunities for the realization of sustainable SME manufacturing. Cooperation with partners like IDN, in the framework of available funding mechanisms, might be a way to support digital transformation, influencing also the environmental performance of the company. Talking about the opportunities Industry 4.0 may bring improvement of the production process; increasing value and improving production process capabilities; and the increased value to the final customer capabilities. Industry 4.0 opportunities are also related to sustainability in SME manufacturing which we will consider from two perspectives: macro and micro, in the next article.

Opportunities related to production process capabilities:

- enhancing the efficiency of the production system;

- improving on-time performance;

- increasing modularity (Stock et al., 2018; Qin, Liu and Grosvenor, 2016);

- increasing integration through data flow and promoting a more flexible structure and data exchange among all the elements (Kagermann, Wahlster and Helbig, 2013; Lasi et al., 2014);

- promoting of intelligent learning analysis (Pagoropoulos, Pigosso and McAloone, 2017; Bonilla et al., 2018);

- self-control and prediction (allowing predictive maintenance) (Bressanelli, 2018);

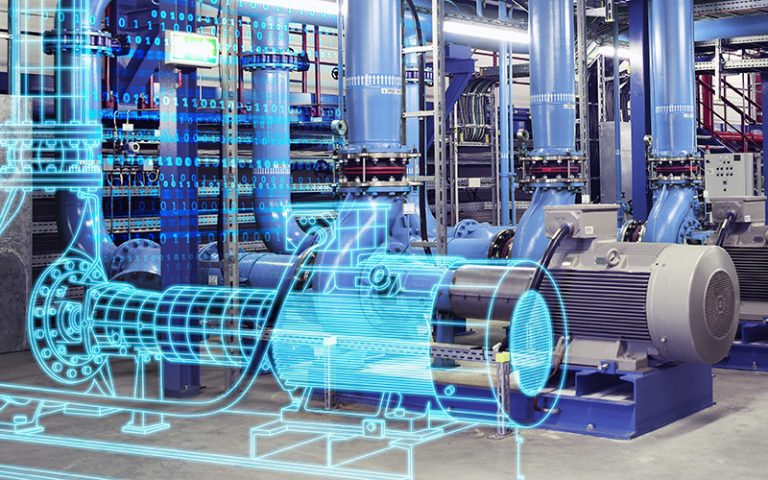

- simulating and modeling of the impact of process-steps and possibility to design and test new plants before set up by virtualization (Stock et al., 2018);

- improving vertical integration of the organization, from product development to manufacturing, logistics, and sales (Kagermann, Wahlster and Helbig, 2013; Deloitte, 2015);

- improving horizontal integration and global optimization of the production process across factory and company boundaries (Kagermann, Wahlster and Helbig, 2013; Kiel et al., 2017; Deloitte, 2015; Bonilla et al., 2018).

Industry 4.0 technologies have huge potential for improvement of the SMEs production process.

Virtual version of factory assets created by Siemen’s Digital Twin technology. Source: AMFG, 2019

Opportunities related to increasing value and improving production process capabilities:

- increasing flexibility, enabling reconfiguration through adapting or changing production requirements or the addition of the machine components (Kagermann, Wahlster and Helbig, 2013; Lasi et al., 2014);

- end-to-end digital integration, allowing the integration of business processes across the entire value chain, including the factory floor and services using Cyber-Physical Systems (CPS) (Kagermann, Wahlster and Helbig, 2013; Wan, Yan and Suo, 2011);

Opportunities related to the increased value to the final customer capabilities:

- increasing customization (Lasi et al., 2014 ;Kiel et al., 2017);

- increasing agility, through the decrease of inventory levels and lead times within the value chain (Stock & Seliger, 2016);

- improving the tracking of raw materials and products during the whole life cycle (Bressanelli et al., 2018);

- the emergence of novel business models, which allow new ways of value creation (Arnold, Kiel and Voigt, 2017; Bonilla et al., 2018).

Implementation of digital technologies, such as automation, digitalization, decentralization, virtualization, real-time data acquisition and processing, and real-time data communication, to manufacturing, suppliers and customers in operational and strategic levels, contribute to the emergence of many opportunities, which can improve production process, integration of business processes across the entire value chain and increase value to the final customer.

Author: Yulia Marchuk